Inkqubo ephezulu yoxinzelelo

Intshayelelo

Umgaqo wamanzi Umgaqo

Impazamo yamanzi ichazwa kwi-NFPA 750 njenge-spisha yamanzi apho i-DVI-0.99. Inkqubo ye-Mill ye-Milt isebenza kwixinzelelo oluphezulu lokuhambisa amanzi njengempazamo yeatom ethandekayo. Le mpazamo iguqulwa ngokukhawuleza ibe yimphunga eyekisa ngomlilo kwaye ithintela ioksijini engaphezulu kokufikelela kuyo. Kwangelo xesha, i-eluperation idala isiphumo esibalulekileyo sokupholisa.

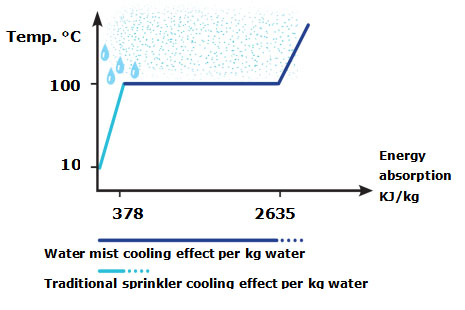

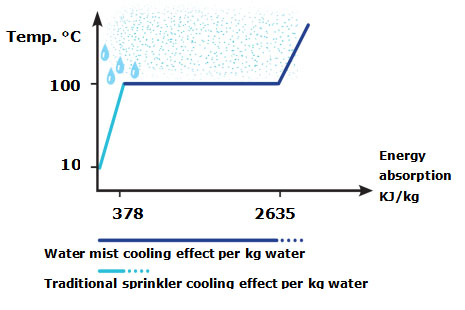

Amanzi anendawo egqwesileyo yobushushu efunxa i-378 kJ / kg. kunye ne-2257 kje / kg. Ukuguqula ukuya kwi-Steam, kunye ne-1700: 1 ukwanda kokwenza oko. Ukwenzela ukuxhaphaza ezi propati, indawo engaphezulu yemigangatho yamanzi kufuneka yenziwe kwaye ixesha labo lokuhamba (ngaphambi kokubetha umphezulu). Ngokwenza njalo, ingcinezelo yomlilo yemililo evuthayo yeflethi inokufezekiswa yindibaniselwano ye

1.Ukukhupha ubushushu kumlilo kunye ne-oyile

2.Ukuncitshiswa kweoksijini nguSteam WOKUGQIBELA KWI-FAMUT

3.Ukuthintela ukutshintshwa kobushushu obuqaqambileyo

4.Ukupholisa iigesi zokudibanisa

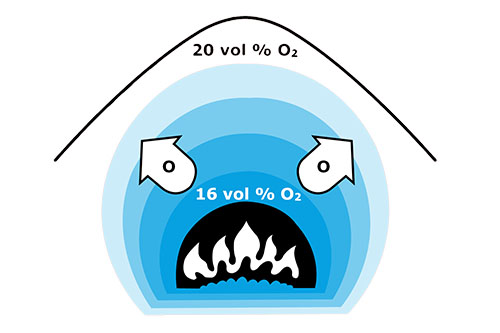

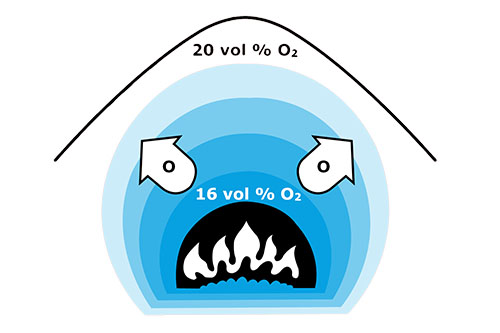

Ngomlilo wokuphila, ixhomekeke kubukho bamazinto ezintathu 'zomlilo unxantathu': ioksijini, ubushushu kunye nezinto ezinokutsha. Ukususwa kwayo nayiphi na kwezi zinto iya kucima umlilo. Inkqubo yoxinzelelo lwamanzi aphezulu e-Inkululeko iyaqhubeka. Ihlasela izinto ezimbini zomlilo: ioksijini kunye nobushushu.

Amachaphaza amancinci kakhulu kwi-drive-cinezela yamanzi e-Mis sy sysker ngokukhawuleza ukuba amasele aphuma kwaye aguqule emanzini, ngenxa yendawo ephezulu yendawo. Oku kuthetha ukuba i-romplet nganye iya kwandisa malunga namaxesha ayi-1700, xa isondele kwinto enokutsha, apho ioksijini iya kushiywa kumlilo, okuthetha ukuba inkqubo edibeneyo iya kungena kwioksijini.

Ukulwa nomlilo, inkqubo yesiqhelo ye-sprink isasaza amaconsi amanzi ngaphezulu kwendawo enikiweyo, efumana ubushushu ukuze uphole igumbi. Ngenxa yobungakanani babo obukhulu kwaye buncinci, eyona ndawo iphambili yamaconsi ayiyi kuthatha amandla aneleyo okuphuma, kwaye bayakhawuleza bawela phantsi njengamanzi. Isiphumo sisiphumo esilinganiselweyo.

Ngokwahlukileyo, inkululeko yamanzi amaninzi iquka amathontsi amancinci kakhulu, awela kancinci. Amanzi amanzi enzonzobila anendawo enkulu yomphezulu ohambelana nobunzima babo kwaye, ngexesha lokuthoba kwabo kumgangatho, bafumana amandla amaninzi. Isixa esikhulu samanzi siya kulandela umgca wokugqibela kwaye sikhuphe, sithetha ukuba amanzi athabatha amandla amaninzi ukusuka kwindawo ekuyo yomhlaba kwaye ngaloo ndlela umlilo.

Yiyo loo nto inkungu yamanzi ephosakeleyo epholileyo esebenzayo ngakumbi ngelitha yamanzi: ukuya kuthi ga kwisixhenxe ilunge ngakumbi kunokuba ifumaneke kwilitha enye yamanzi esetyenziswe kwiNkqubo yeSiko.

Intshayelelo

Umgaqo wamanzi Umgaqo

Impazamo yamanzi ichazwa kwi-NFPA 750 njenge-spisha yamanzi apho i-DVI-0.99. Inkqubo ye-Mill ye-Milt isebenza kwixinzelelo oluphezulu lokuhambisa amanzi njengempazamo yeatom ethandekayo. Le mpazamo iguqulwa ngokukhawuleza ibe yimphunga eyekisa ngomlilo kwaye ithintela ioksijini engaphezulu kokufikelela kuyo. Kwangelo xesha, i-eluperation idala isiphumo esibalulekileyo sokupholisa.

Amanzi anendawo egqwesileyo yobushushu efunxa i-378 kJ / kg. kunye ne-2257 kje / kg. Ukuguqula ukuya kwi-Steam, kunye ne-1700: 1 ukwanda kokwenza oko. Ukwenzela ukuxhaphaza ezi propati, indawo engaphezulu yemigangatho yamanzi kufuneka yenziwe kwaye ixesha labo lokuhamba (ngaphambi kokubetha umphezulu). Ngokwenza njalo, ingcinezelo yomlilo yemililo evuthayo yeflethi inokufezekiswa yindibaniselwano ye

1.Ukukhupha ubushushu kumlilo kunye ne-oyile

2.Ukuncitshiswa kweoksijini nguSteam WOKUGQIBELA KWI-FAMUT

3.Ukuthintela ukutshintshwa kobushushu obuqaqambileyo

4.Ukupholisa iigesi zokudibanisa

Ngomlilo wokuphila, ixhomekeke kubukho bamazinto ezintathu 'zomlilo unxantathu': ioksijini, ubushushu kunye nezinto ezinokutsha. Ukususwa kwayo nayiphi na kwezi zinto iya kucima umlilo. Inkqubo yoxinzelelo lwamanzi aphezulu e-Inkululeko iyaqhubeka. Ihlasela izinto ezimbini zomlilo: ioksijini kunye nobushushu.

Amachaphaza amancinci kakhulu kwi-drive-cinezela yamanzi e-Mis sy sysker ngokukhawuleza ukuba amasele aphuma kwaye aguqule emanzini, ngenxa yendawo ephezulu yendawo. Oku kuthetha ukuba i-romplet nganye iya kwandisa malunga namaxesha ayi-1700, xa isondele kwinto enokutsha, apho ioksijini iya kushiywa kumlilo, okuthetha ukuba inkqubo edibeneyo iya kungena kwioksijini.

Ukulwa nomlilo, inkqubo yesiqhelo ye-sprink isasaza amaconsi amanzi ngaphezulu kwendawo enikiweyo, efumana ubushushu ukuze uphole igumbi. Ngenxa yobungakanani babo obukhulu kwaye buncinci, eyona ndawo iphambili yamaconsi ayiyi kuthatha amandla aneleyo okuphuma, kwaye bayakhawuleza bawela phantsi njengamanzi. Isiphumo sisiphumo esilinganiselweyo.

Ngokwahlukileyo, inkululeko yamanzi amaninzi iquka amathontsi amancinci kakhulu, awela kancinci. Amanzi amanzi enzonzobila anendawo enkulu yomphezulu ohambelana nobunzima babo kwaye, ngexesha lokuthoba kwabo kumgangatho, bafumana amandla amaninzi. Isixa esikhulu samanzi siya kulandela umgca wokugqibela kwaye sikhuphe, sithetha ukuba amanzi athabatha amandla amaninzi ukusuka kwindawo ekuyo yomhlaba kwaye ngaloo ndlela umlilo.

Yiyo loo nto inkungu yamanzi ephosakeleyo epholileyo esebenzayo ngakumbi ngelitha yamanzi: ukuya kuthi ga kwisixhenxe ilunge ngakumbi kunokuba ifumaneke kwilitha enye yamanzi esetyenziswe kwiNkqubo yeSiko.

1.3 I-Suporence Watch Andrance Forem Intshayelelo Inkqubo

Inkqubo ephezulu yoxinzelelo lwe-Mill System yinkqubo yokucima umlilo eyahlukileyo. Amanzi anyanzelwa nge-nozzles ezincinci kuxinzelelo olukhulu ukwenza impumlo yamanzi kunye neyona ndawo isebenzayo yobukhulu bokusasazwa komlilo. Iziphumo ezigxothiweyo zibonelela ngokhuseleko olukhethekileyo ngokupholisa, ngenxa yokufumana ubushushu, kwaye zingena ngenxa yokwanda kwamanzi ngamaxesha angama-1,700 xa ikhutshiwe.

1.3.1 icandelo eliphambili

I-Nozzles eyile

I-nozzles ePhezulu yamanzi ama-Nozzles zisekwe kubuchwephesha bee-nozzles ze-nor. Ngenxa yefom yazo ekhethekileyo, amanzi afumana isondo olujikelezayo kwigumbi le-Swilil kwaye ngokukhawuleza aguqulwe kakhulu yimpazamo emanzi abhalwe emlilweni ngesantya esikhulu. I-angle enkulu ye-SPRY kunye nepateni yokutshiza ye-nezzles ezincinci zenza ukuba isithuba esiphezulu.

Amaconsi asekwe kwiintloko ze-nozzle adalwe usebenzisa phakathi kwe-100-120 yeengcibi zoxinzelelo.

Emva kothotho lweemvavanyo ezinzulu kakhulu kunye novavanyo lwezinto ezibonakalayo, ii-nozzles zenziwa ngokukodwa kwimpazamo enkulu yamanzi. Zonke iimvavanyo ziqhutywa ngamalabhoratri ezimeleyo ukuze kwanesidingo esingqongqo kakhulu kunxweme.

Uyilo lwempompo

Uphando olunzulu lukhokelele ekudalweni kweyona ndawo iphosakeleyo yehlabathi kunye neyona nto iphambili kwimpompo. Iimpompo ze-piston ze-axial piston zenziwe kwinsimbi enganyangekiyo enganyangekiyo. Uyilo oluyedwa lusebenzisa amanzi njengeoli, kuthetha ukuba iinkqubo zenzala kwaye zithathe indawo ye-i-ibricants azidingeki. Impompo ikhuselwe ngamalungelo awodwa omenzi wamanye amazwe kwaye isetyenziswa ngokubanzi kwiinxalenye ezininzi ezahlukeneyo. Iipumps zinikela ukuya kuthi ga kwi-95% yokusebenza kakuhle kunye nokudubula okuphantsi kakhulu, ngaloo ndlela kuncitshiswa ingxolo.

Ivali enkulu kakhulu

Iicalve zoxinzelelo oluphezulu zenziwa kwintsimbi engenasimo kwaye zibubungqina obuninzi kunye nobumdaka. Uyilo lweBhloko lokuThembisa luyenza iivalvu kakhulu, ezibenza zibe lula kakhulu ukuba zifake kwaye zisebenze.

1.3.Iinzuzo ezi-2 zenkqubo ephezulu ye-Milt Pro

Izibonelelo zenkqubo ephezulu ye-Milt Proure System. Ukulawula / ukubeka umlilo ngemizuzwana, ngaphandle kokusebenzisa naziphi na iinyikimi kunye nokusetyenziswa kwamanzi kunye nokusondeza kungekho sonakaliso lwamanzi, yenye yeenkqubo ezinobuhlobo bokuhlonitshwa, kwaye zikhuselekile ngokupheleleyo ebantwini.

Ubuncinci bokusetyenziswa kwamanzi

• Umonakalo wamanzi

• Umonakalo omncinci kwisiganeko esingalindelekanga sokuvula ngengozi

• I-Finess encinci yenkqubo yokusebenza kwangaphambili

• Inzuzo apho kukho imbopheleleko yokubamba amanzi

• Indawo yokugcina inqabile

• Ukukhuselwa kwendawo ikunika ukhawulezisa ukulwa umlilo

• Ixesha elincinci lokuphumla ngenxa yomlilo ophantsi kunye nomonakalo wamanzi

• Ukuncitshiswa komngcipheko wokuphulukana nentengiso yentengiso, njengoko imveliso iyakhawuleza kwaye isebenza kwakhona

• Ukusebenza ngokufanelekileyo-nakwimililo yokulwa ioyile

• Iindleko zokubonelela ngamanzi asezantsi okanye irhafu

Imibhobho yentsimbi engenanto

• lula ukufaka

• Kulula ukuphatha

• Isondlo Simahla

• Uyilo olunomtsalane kubandakanywa lula

• Umgangatho ophezulu

• ukuqina okuphezulu

• Ixabiso elisebenzayo kwinqanaba

• Cinezela ngokufanelekileyo ufakelo olukhawulezileyo

• Kulula ukufumana igumbi lombhobho

• Kulula ukubuyisela kwakhona

• Kulula ukugoba

• Zimbalwa izixhobo ezifunekayo

Ii-nozzles

• Ukwazi ukupholisa kwenza ukuba ukufakwa kwefestile yeglasi kumnyango womlilo

• Ukuhlelwa okuphezulu

• Bambalwa i-nozzles-oyithandayo

Ukuphola ngokufanelekileyo

Ukupholisa kwewindows-Yenza ukuthengwa kweglasi yexabiso eliphantsi

• Ixesha lokufaka elifutshane

• Uyilo lobuhle

1.3.3 Imigangatho

I-1. NFPA 750 - Uhlobo luka-2010

Inkcazo yeNkqubo yeNkqubo kunye nezinto

2.1. Intshayelelo

Inkqubo ye-HPWM iya kuba nenani le-nozzles exhunyiwe yi-stainces yentsimbi ukuya kumthombo wamanzi oxinzelelo lwamanzi (iiyunithi zempompo).

2.2 I-Nozzles

I-HPWM Ii-Nozzzles zichanekile izixhobo ezichanekileyo, zenzelwe ukuxhomekeka kwisicelo senkqubo ukuhambisa i-interher yento eqinisekisa ukucinezelwa komlilo, ukulawula okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima okanye ukucima.

2.3 I-valves i-valves - inkqubo evulekileyo ye-nozzle

I-valve zeCandelo zinikezelwa kwinkqubo yokucima umlilo nge-fireffirieff ukwenzela ukwahlula amacandelo omlilo.

I-valve ze-valve zenziwa ngentsimbi engenasimo kwicandelo ngalinye lokukhuselwa linikezelwa ekufakweni kwinkqubo ye-pipe. I-valve yecandelo idla ivaliwe kwaye ivuliwe xa inkqubo yokucima umlilo isebenza.

Ilungiselelo le-valve ye-veli linokudityaniswa ngokudibeneyo kwi-Inteold eqhelekileyo, kwaye ke loo nto ifakwe kwi-nozzles kwi-nozzles ifakwe. I-valve yeCandelo zinokunikezelwa ngokufakwa endaweni yokufakelwa kwinkqubo yombhobho kwiindawo ezifanelekileyo.

I-valve zeCandelo kufuneka zibekwe ngaphandle kwamagumbi akhuselweyo ukuba ayizizo ezinye zichaziwe yimigangatho, imigaqo yesizwe okanye igunya.

I-valve yecandelo le-syves lisekwe kwicandelo ngalinye loyilo.

Icandelo lenkqubo lenkqubo linikezelwa njengevalve esebenza ngombane. I-Compoves Eemoto ezisebenza ngeZithuthi eziSebenzayo zihlala zifuna umqondiso wama-230 wokugoba.

Ivalve ihlanganisene kwangaphambili kunye noxinzelelo kunye ne-valves yedwa. Inketho yokubeka i-valves yodwa iyafumaneka kunye nezinye izinto ezahlukeneyo.

2.4Impompoiyunithi

Iyunithi yempompo iya kusebenza ngokuqhelekileyo phakathi kwe-100 ye-100 ye-100 ye-14 Iinkqubo zempompo zinokusebenzisa iiyunithi enye okanye ezingaphezulu zempompo ezinxulumene nokusetyenziswa kwenkqubo yamanzi ye-Mill ukuhlangabezana neemfuno zoyilo lwenkqubo.

2.4.1 Iimpompo zombane

Xa inkqubo yenziwe, impompo enye kuphela iya kuqalwa. Iinkqubo ezibandakanya ngaphezulu kwempompo enye, iimpompo ziya kuqalwa ngokulandelelana. Ukuba ukunyuka kwendlela yokuhamba ngenxa yokuvulwa kweengazuzana ngakumbi; Impompo eyongezelelweyo (s) iya kuqala ngokuzenzekelayo. Kuphela ziimpompo ezininzi njengoko kufuneka zigcine ukuhamba nokusebenza koxinzelelo rhoqo kunye noyilo lwenkqubo luya kusebenza. Inkqubo ephezulu yoxinzelelo lwamanzi Hounts ihleli isebenza de kwabasebenzi abaqeqeshiweyo okanye ukucima umlilo.

Iyunithi esemgangathweni yePump

Iyunithi yempompo yindawo enye edityanisiweyo ye-skidi enyukayo eyenziwe ngeendibano zilandelayo:

| Icandelo lokucoca | I-Buffer Tank (ixhomekeke kwixinzelelo lwe-inlet kunye nohlobo lwempompo) |

| Itanki iphezulu kunye nenqanaba lomgangatho | I-Tank inlet |

| Buyisa umbhobho (ungayikhokelela kwi-Outlet) | I-Inlet i-Intelold |

| I-Suction Lite Aneold | Iyunithi ye-HP ye-HP |

| (S) | Cineze |

| Impompo ye-Pilot | Iphaneli yokulawula |

2.4.2I-Pump yePaneli yePump

Iphaneli yokulawula iimoto injengoko inyuswe kwiyunithi yempompo.

Uncedo lwamandla aqhelekileyo njengomgangatho: 3x400v, i-50 hz.

Impompo (s) ithe ngqo kumgca oqalisiweyo njengomgangatho. Qala-Delta uqalisa, ukuthamba okuthambileyo ukuqala kunye nokuguqula rhoqo kunganikezelwa njengokukhetha ukuba kuncitshiswe ukuba kuyafuneka okwangoku.

Ukuba iyunithi yempompo iqulathe ngaphezulu kwempompo enye, ulawulo lwexesha lokudibanisa ngokuthe ngcembe lwepumps luzisiwe ukufumana ubuncinci bomthwalo wokuqala.

Iphaneli yokulawula ine-ral 7032 yokugqitywa kwenqanaba lokukhusela i-IP54.

Ukuqala kweempompo kufezekiswa ngolu hlobo lulandelayo:

Iinkqubo ezomileyo- ukusuka kumdlalo we-volt-sasimahla

Iinkqubo ezimanzi-ukusuka kwihlaso kwi-cinezela, iliso yiphaneli ye-pump ye-pump.

Inkqubo yentshukumo yangaphambi-idinga iimpawu ezivela kuzo zombini intlawulo yomoya kwinkqubo kunye noqhakamshelwano lwe-volt-free project ebonelelwe kwiPhaneli yoLawulo lweMililo.

2.5Ulwazi, iitafile kunye nemizobo

2.5.1 I-Nozzle

Kufuneka kuthathwe ukhathalelo olukhethekileyo ukuthintela izithintelo xa uyila iinkqubo zenkuni, ngakumbi xa usebenzisa ukuhamba okuphantsi, ubungakanani obuphawu obuncinci njengoko intsebenzo ichaphazeleke kakubi kukuthintelwa. Oku krwada kuba ukuxinana kwe-flux kufezekiswa (ngale-nozzles) ngomoya ovuthuzayo ngaphakathi kwegumbi lokuvumela ukuba kungabikho khupha i-rous ukuba ingasasazeki kwi-DEAP NOKWENZA ISIQINISEKISO SE-DORTER ngaphandle kokusasaza ngokulinganayo ngaphakathi kwesithuba.

Ubungakanani kunye nomgama ukuya kuthintelwa kuxhomekeka kuhlobo lwe-nozzle. Olu lwazi lunokufumaneka kwiphepha ledatha le-nozzle ethile.

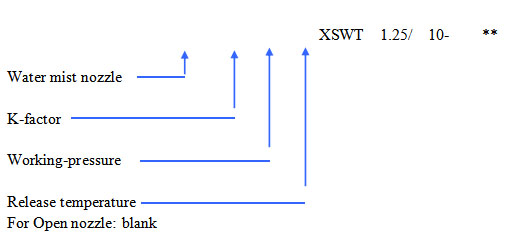

Umzobo 2.1 I-Nozzle

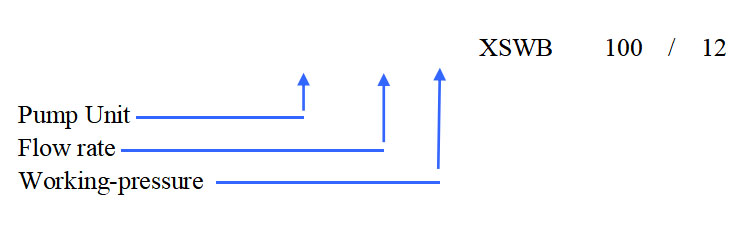

2.5.2 Iyunithi yePump

| Uhlobo | Imveliso l / min | Amandla KW | Iyunithi esemgangathweni ye-Pump enePaneli yoLawulo L x w x h mm | Oulet mm | Ubunzima beyunithi kg malunga |

| I-XSWB 100/12 | I-100 | 30 | Ngo-1960×I-430×I-1600 | Ø42 | 1200 |

| I-XSWB 200/12 | 200 | 60 | 2360×I-830×I-1600 | Ø42 | 1380 |

| I-XSWB 300/12 | I-300 | 90 | 2360×I-830×I-1800 | Ø42 | I-1560 |

| I-XSWB 400/12 | I-400 | I-120 | 2760×I-1120×Ngo-1950 | Ø60 | I-1800 |

| I-XSWB 500/12 | I-500 | I-150 | 2760×I-1120×Ngo-1950 | Ø60 | Ngo-1980 |

| I-XSWB 600/12 | I-600 | I-180 | 3160×1230×Ngo-1950 | Ø60 | 2160 |

| I-XSWB 700/12 | I-700 | I-210 | 3160×1230×Ngo-1950 | Ø60 | 2340 |

Amandla: 3 X 400VAC 50h 1480 RPM.

Iyunithi yePump 2.2

2.5.3 Iindibano zeValve

Iindibano eziqhelekileyo ze-valve ziboniswe ngaphantsi komfu 3.3.

Indibano ye-valve iyacetyiswa kwi-CORTI-SURD STEDS ukusuka kubonelelo lwamanzi elinye. Olu hlengahlengiso luya kuvumela amanye amacandelo okuhlala ahlala esebenza ngelondolozwe kwicandelo elinye.

I-MFI 2.3 -3 - INdibano yePalve yesiqhelo